Silicone Custom Component Solutions

SHENGHUI provides comprehensive turnkey solutions for businesses requiring high-performance Liquid Silicone Rubber (LSR) and High Consistency Rubber (HCR) injection-molded parts. Our team assists in selecting the ideal material for your project and offers tailored tooling solutions to meet your production needs.

Before manufacturing, our skilled engineers provide detailed specifications for your approval. During production, your components undergo rigorous quality assurance, ensuring top-tier standards with one of the industry’s lowest defect rates. Additionally, we design cost-efficient packaging to minimize your shipping and transportation costs.

Parts in as fast

as 3 days

ISO 9001:2015

Certified

- All uploads are secure and confidential.

Custom Silicone Molding Services

SHsilicagel provides comprehensive turnkey solutions for any business requiring high-performance silicone rubber injection-molded parts. We assist you in selecting the right materials for your upcoming projects and offer tooling solutions best suited to meet your ongoing production needs.

One-Stop Silicone Product Solution

At ShengHui, we empower your journey from initial concept to final product with our comprehensive prototyping and production solutions.

PROTOTYPING

Rapid Prototyping

We transform your ideas into precise, real prototypes, accelerating product development with silicone molding technologies. Our approach includes silicone mold manufacturing and related techniques, enabling rapid testing and validation of parts, smoothing the path from concept to market.

- Adoption of LSR and touch moulding, etc.

- Quickly iterate and refine designs with high accuracy.

- Ensure prototypes meet your exact specifications.

PRODUCTION

Low and High-Volume Production

ShenHui’s digital manufacturing ecosystem robustly supports seamless mass production with an innovative quoting system, a vast network of partners, and state-of-the-art facilities. This ensures consistent quality and competitive pricing for all custom production needs.

- Streamlines production processes.

- Offers diverse manufacturing capacity.

- Meets tight deadlines with consistent results.

Some Number About Us

40+

Customer Served

100,000+

30+

Countries & Regions Shipped

20+

Manufacturing Partners

5 Years Experience

in silicone prototype and part manufacturing.

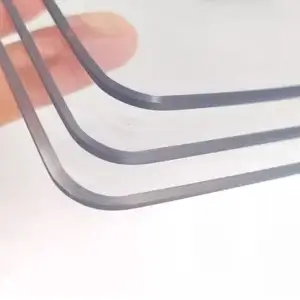

Featured Silicone Products We Make

Why Choose Shenghui – Your Silicone Products Expert

01

Material Formula Test Lab

ShengHui silica gel has its own material formula testing laboratory equipped with professional measuring equipment, providing precise DFM+CPK reports. We conduct various tests, including evaluations of polymer materials, vinyl and phenyl content, elemental analysis, and tests using a rubber processing analyzer. This ensures the correct proportions of silicone, rubber, and other additives in each product.

02

Mold Workshop

Our mold workshop houses over 1,400 different molds and can create custom molds tailored to your specifications. We collaborate closely with customers from the start when designing personalized silicone products. Based on your ideas or designs, we develop 3D CAD files for you. Our advanced CNC tooling and EDM machines then use these files to produce your custom mold.

03

Injection Molding

The ShengHui silica gel factory operates 10 lines dedicated to solid silicone injection molding. This process utilizes high pressure and heat to inject silicone rubber into molds. Injection molding is renowned for its capability to achieve high precision, consistency, and accommodate complex designs. However, it is more cost-effective for high-volume production due to significant initial and ongoing equipment investment costs associated with this technology.

04

Cleaning & Packaging

We have established partnerships with packaging supply companies to help you choose the perfect packaging solution based on your budget, product type, and shipping requirements. Before shipment, we meticulously clean all silicone rubber products to ensure they arrive in optimal condition.

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

RTS

- Inquiry Online Directly

- Color/ Size/ Qty

- Address/ Transport

- Quality Certificate

Confirm With Sales

- Proforma Invoice

- Payment

Shipment

- Commercial Invoice

- Payment

Strict Quality & Control Process

- Raw Material Testing

- IPQC

- Signed Sample

- Mass Production

- IPQC Random Inspection

- IQC

- Warehousing Conditions

- First Production Sample Checking

- AOI Checking

- Final Inspection

Custom Silicone Parts for Any Industry

Our services extend across various industries, including automotive, medical, and consumer goods, offering versatile and adaptive solutions for every sector.

Blogs

Check out the latest industry trends and take inspiration from our updated blogs, giving you a fresh insight to help boost your business.

Unveiling the Fatigue Characteristics of Liquid Silicone Rubber

In the realm of materials